-

A rapid industrial heat transition will contribute to climate protection and is necessary to fulfil Germany‘s contribution to reducing natural gas consumption as part of REPowerEU.

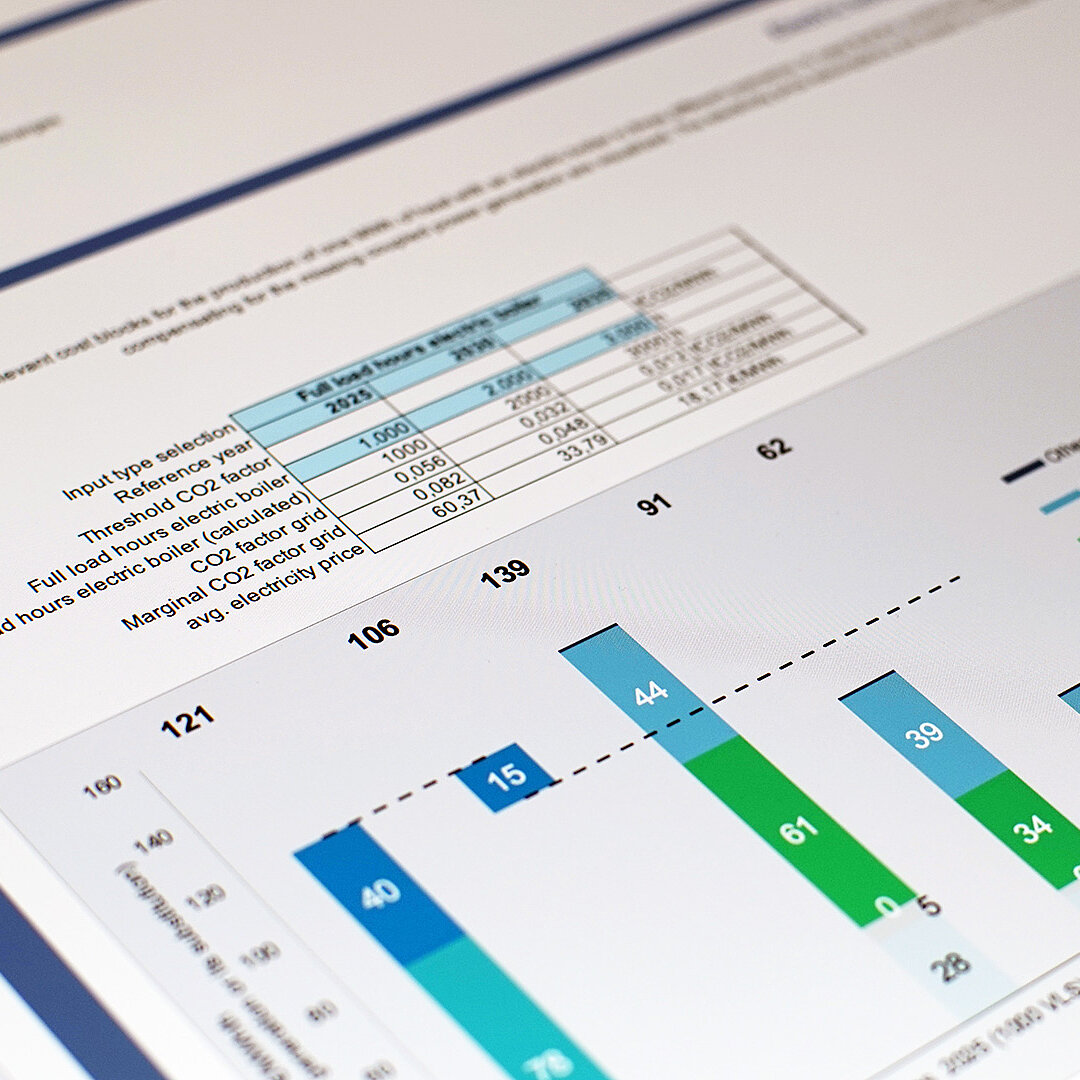

By 2030, industrial plants in Germany can save 90 TWh of natural gas through the electrification of process heat. This represents up to three quarters of the savings required from industry by the REPowerEU plan and a reduction of 12.5 million tonnes of CO₂ – 18 percent of the target for the industrial sector in the German climate protection law.

-

The use of heat pumps and electric boilers in industry must proceed in tandem with the decarbonisation of the electricity sector.

Flexible electricity consumption helps to integrate a high share of renewable energy and to make better use of its volatile generation. Such flexibility will make it possible to meet the German government‘s target of 80 percent renewables by 2030 efficiently.

-

Removing regulatory barriers and perverse incentives makes electrification more attractive and enables flexibility.

In order to stimulate flexible consumption, the introduction of time-differentiated grid charges must be made a political priority. Likewise, privileging natural gas-based technologies over applications using direct electricity must end.

-

In the German Energy Security Act, the year 2035 should be set as the deadline for the phase-out of fossil fuels in process heating up to 500 degrees.

A special support programme can be used to close the cost gap for electricity-based technologies, and a statutory zero carbon standard for new investments can create planning and investment certainty.

This content is also available in: German

Power-2-Heat

Gas savings and emissions reduction in industry

Preface

Russia’s attack on Ukraine has intensified the need to rapidly reduce the consumption of fossil fuels, and of natural gas in particular. In addition to short-term measures to save gas in response to the energy crisis, there is also a need to focus on a structural reduction in industrial consumption of natural gas.

The EU Commission’s REPowerEU plan calls on industry to reduce its natural gas consumption by around half by the year 2030. The Federal Climate Protection Act requires a reduction of around a third of industrial greenhouse gas emissions by 2030.

This study demonstrates the potential for the direct electrification (Power-2-Heat) of industrial process heat up to 500 degrees Celsius, as used for example in the paper, food and plastics industries, in pursuit of these targets.

By switching to electricity-based processes for industrial heat generation, both natural gas consumption and greenhouse gas emissions are significantly reduced. In addition, these processes support the integration of renewable energies as they offer flexible electricity consumption.

In order to facilitate the market ramp-up of these processes through a combination of subsidies and regulatory standards, a number of regulatory barriers must be removed. In our study, we show how this can be achieved.

Key findings

Bibliographical data

Downloads

-

Main Report

pdf 3 MB

Power-2-Heat

Gas savings and emissions reduction in industry

All figures in this publication

The role of process heat in the German energy system and its share of German natural gas consumption

Figure 1 from Power-2-Heat on page 8

Final energy demand for the generation of industrial process heat by temperature level

Figure 2 from Power-2-Heat on page 9