German industrial heat transition can deliver three quarters of the sector’s required gas savings under REPowerEU

Using heat pumps and electric boilers instead of gas in its low-temperature process heat, German industry can achieve gas savings worth 90-terawatt hours and avoid 12.5 million metric tons of C02 by 2030. The transition comes for a fraction of what the German government plans to spend on protecting industry from high gas prices.

Berlin, 16 November 2022. German industry can achieve gas savings worth around 90-terawatt hours by 2030 if it electrifies process heat up to 500 degrees Celsius, a study by Agora Industry finds. This corresponds to three-quarters of German industry’s share of fossil gas savings under the European REPowerEU plan to reduce dependence on Russian fossil fuels. At the same time, the use of heat pumps and electric boilers avoids 12.5 million metric tons of CO₂, which equals to around one-fifth of the target for the industrial sector by 2030 under the German Climate Change Act.

“Our study shows that even for a very large industrial gas consumer like Germany it is possible to achieve the goals of REPowerEU, if the right policy framework is in place,” said Frank Peter, director of Agora Industry.

The think tank proposes a package of policy measures that can enable electrification of industrial process heat up to 500 degrees at low cost: Weaning off industry from fossil fuels in low temperature process heat requires investments of around 12 bn euros until 2030 – a small sum compared to what the German government plans to spend on protecting industrial consumers from high gas prices in the next two years. At the same time, the potential for electrification is huge as almost half of industrial process heat demand is below 500 degrees Celsius; a good third is even below 200 degrees Celsius.

The proposed policy package includes subsidies to mitigate investment risks, clear standards for new investments, and incentives for flexible electricity consumption. A central component is to anchor a phase-out of fossil fuels for process heat up to 500 degrees by 2035. "Defining a phase-out date for the use of fossil fuels in industrial process heat where it is technically feasible creates planning and investment certainty for businesses and puts us on track towards climate neutrality," says Agora Industry Director Peter.

In addition, the think tank proposes to launch a special support programme to close the cost gap for electricity-based technologies and establish a legal zero-carbon standard for new investments. “To ensure that heat pumps and electric boilers are available to industry, a joint strategy is needed from policymakers, industry, equipment manufacturers and trade chambers,” Peter said.

To kick-start the industrial heat transition, governments need to remove regulatory barriers quickly. Currently, in the EU emissions trading system, energy-intensive industries receive on average more than 80 percent of their CO2 certificates for free. This delays the transition to carbon-free heat production to the 2030s. In Germany, the energy tariff structure further favours fossil fuels and inflexible demand. Tax exemptions favour cogeneration plants over electricity-powered heat generators and the structure of grid charges incentivises high, uniform electricity consumption.

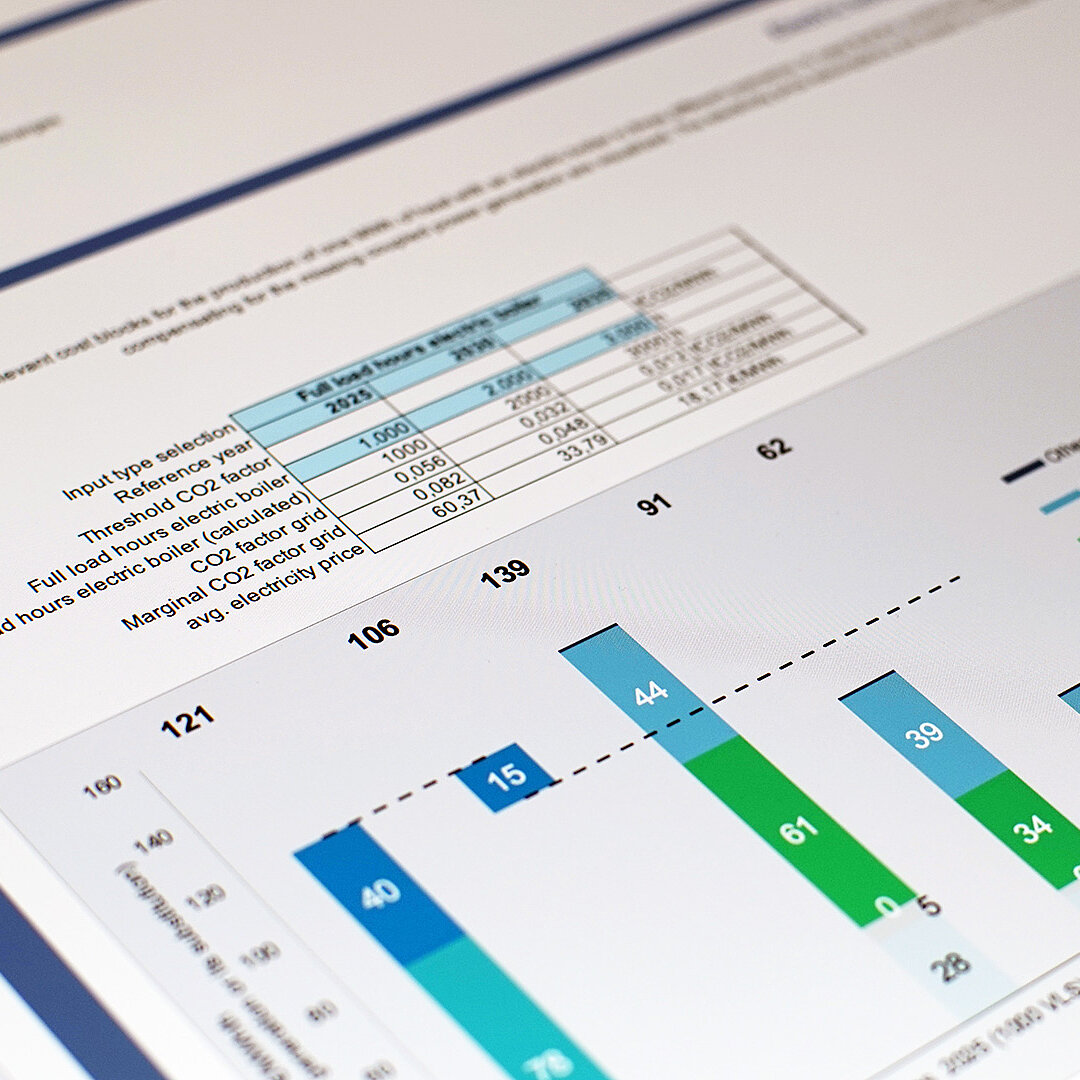

The study "Power-2-Heat: Gas savings and emissions reduction in industry" was produced in collaboration with FutureCamp. The publication is available for free download at www.agora-industrie.org. Accompanying the study, Future Camp and the Wuppertal Institute developed a calculator to estimate the transformation costs from natural gas to heat pumps and electrode boilers. The Excel tool is available for free download below.