- Authors

- Caroline Paul, Matthias Deutsch, Emir Çolak

- Version number

- 1.0

- Publication date

-

6 June 2024

- Suggested Citation

- Agora Industry (2024): Global Green Fertiliser Tracker, Model version 1.0, Berlin, 06.06.2024

- Project

- This publication was produced within the framework of the project Global Green Fertiliser Tracker.

Global Green Fertiliser Tracker

A digital resource to monitor the transformation of global synthetic nitrogen fertiliser production towards climate neutrality and gauge the implementation gap until 2030

About this tool

The Global Green Fertiliser Tracker is an innovative digital resource designed to monitor and support the transformation of global nitrogen fertiliser production toward renewable energy sources. It sheds light on pioneering projects that are already in operation and on the outlook of the fertiliser industry transformation. The tracker will be updated on a regular basis as we learn about new projects, ensuring that it remains current and providing valuable information to all stakeholders within the agricultural and chemical industries.

State of play of nitrogen fertiliser production

Synthetic nitrogen fertilisers have allowed humans to increase agricultural productivity tremendously. Nitrogen is one of the three macronutrients indispensable for plant growth.

Ammonia is the basic building block for modern nitrogen fertiliser and consists of hydrogen and nitrogen. 70 percent of all ammonia produced globally is used for nitrogen fertilisers. Its production currently requires fossil fuels – mainly gas and to some extent coal – to derive the hydrogen molecule. This is highly energy and emissions intensive. Adding nitrogen using the Haber-Bosch process further increases energy-related emissions. Thus, about one percent of total global energy-related and industrial CO2 emissions result directly from ammonia production.

Figure 1: Why transforming current nitrogen fertiliser production?

Advancing nitrogen fertiliser production to renewable sources

The main ingredients for renewable ammonia production are renewable electricity and water. Replacing fossil-based ammonia with ammonia from renewable sources can eliminate almost all greenhouse gas emissions linked to the production of nitrogen fertilisers. Low-carbon production pathways, sorted from high to low emissions are:

- low-carbon fertiliser, produced from fossil fuels with carbon capture

- low-carbon fertiliser produced from fossil fuels and up to 15 percent renewable H2 fed into a conventional SMR/ATR process

- biomass-based renewable fertilisers with conventional SMR/ATR

- renewable fertilisers produced by electrolysis and an air separation unit to capture nitrogen from air.

Figure 2: Advancing nitrogen fertiliser production to renewable sources

Low carbon fertilisers are not fit to achieve net-zero emissions due to upstream methane leakages and residual emissions from incomplete carbon capturing. In case of the biomass route, limited availability of sustainable biomass in many regions of the world will affect their production capacities. Fertilisers produced from renewable hydrogen via electrolysis are clearly in the lead in terms of emissions-savings potential and sustainability issues.

Sustainability aspects beyond renewable production

To produce fertiliser in line with different sustainability dimensions, it needs to be ensured that:

- renewable energy resources for hydrogen production are additional

- the biomass feedstock comes from sustainable sources

- carbon for urea production be sourced sustainably

- water required for hydrogen production be sourced sustainably without exacerbating local water stress.

Beyond GHG emissions from fertiliser production, the application of nitrogen fertilisers in the field can cause numerous environmental problems. The focus is on nitrogen surpluses, i.e. the proportion of fertiliser that is not absorbed by the plants and is removed with the harvest. Avoiding nitrogen surpluses and emissions of reactive nitrogen (N) compounds is among the most important agri-environmental measures, as nitrogen pollution contributes to the exceeding of almost all planetary boundaries. Excess nitrogen is emitted as nitrous oxide into the atmosphere, ammonia into the air and nitrate into the groundwater. Against this background, improving nitrogen use efficiency in agriculture is key to mitigating the environmental problems of nitrogen fertilisation. To achieve this, fertilisers have to be applied at the right time, the right rate, the right place and with the right type.

Sustainability aspects beyond renewable production

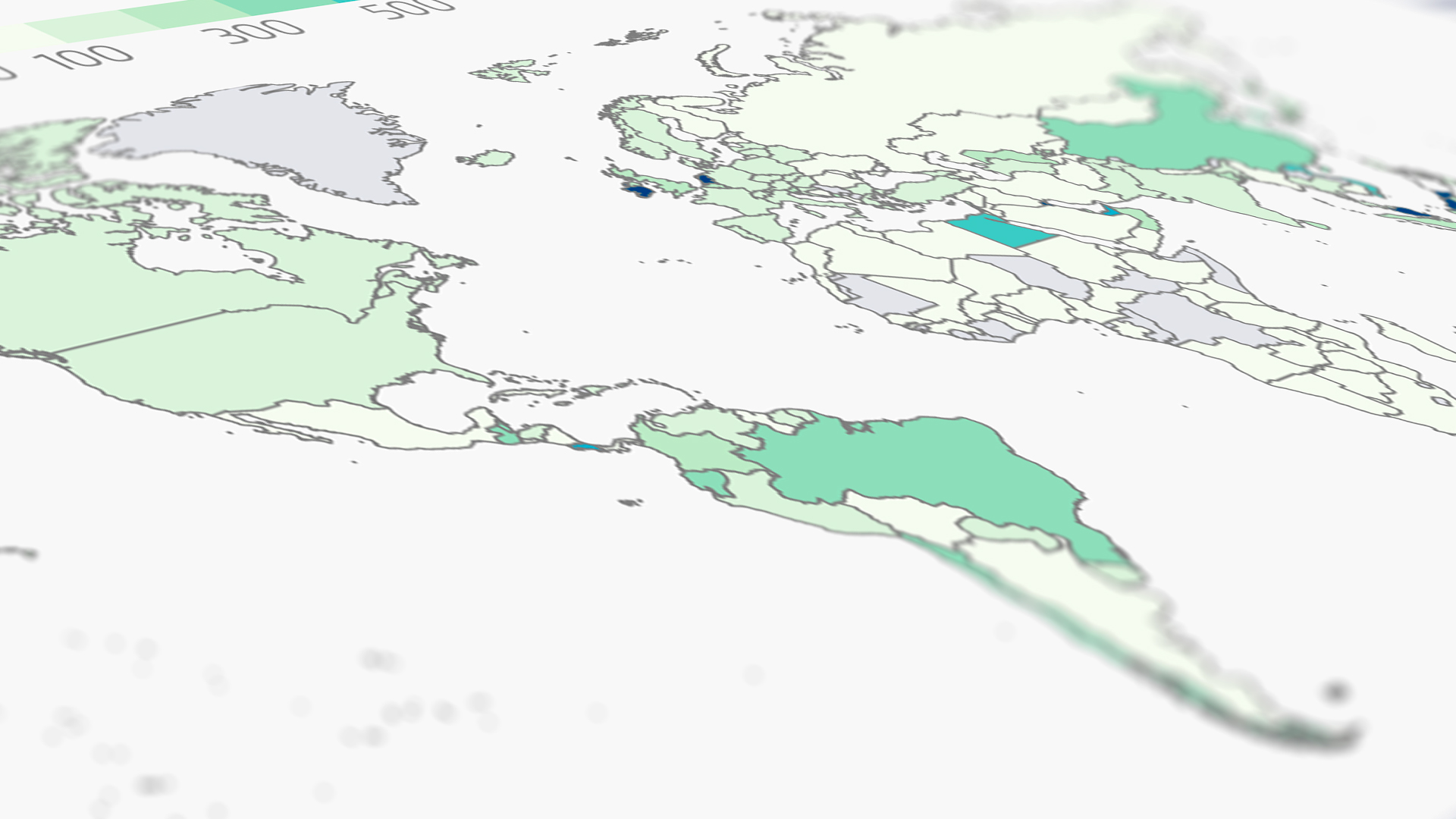

Renewable fertiliser projects : Like a drop in the ocean

Only small steps have been taken by a few frontrunners in the fertiliser industry: By mid-2024, we have counted only four renewable fertiliser production sites in operation and another four sites in commissioning, very likely to start production in 2024. This stands in stark contrast to the large number of project announcements.

All projects in the tracker are still at the pilot stage, with plans to scale them up in future. Electrolytic hydrogen is either used directly for renewable ammonia production or feeds into conventional ammonia production as a quota. Most projects are co-located with an existing large-scale ammonia plant and operated by established fertiliser producers. Two projects are operated by consortia in start-up stage which have built small-scale greenfield facilities adjacent to agricultural producers they will supply. Electrolyser capacities range from 0.25 Megawatts (MW) to 24 MW. One project uses biomethane as renewable feedstock.

Solar PV dominates as a source of renewable electricity among early movers. Most projects source energy from Solar PV from dedicated installations with an installed capacity of 121 MW across five projects. Two other projects are run by grid electricity, connecting the emissions intensity of ammonia with the grid.

Renewable ammonia capacity dedicated to nitrogen fertilisers is tiny. Summing up all reported production sites, it amounts to approx. 61 kt per annum which corresponds to 0.3 percent of all global ammonia used for nitrogen fertiliser production.

Renewable fertiliser projects in operation worldwide

Who will bear the extra cost?

Renewable hydrogen will remain costly in the near future, adding significant extra costs to renewable fertilisers when compared to conventional ones. But who will bear the extra cost? It can be expected that only few farmers would buy a more expensive agrochemical which is identical to the cheaper conventional product. So who will be the offtaker?

Already now, major food and beverage producers are willing to pay this green premium today because they have committed to greenhouse gas emission reduction trajectories. They have signed offtake agreements with renewable fertiliser producers. Typically, crops fertilised in these early-mover projects are grains, potatoes or tomatoes. They are processed into bread, crisps or beer. In these products, the green premium only adds a few cents more to the final product price while substantially reducing the product’s carbon footprint .

Who will bear the extra cost?

Closing the transformation gap

While small first steps have been taken to defossilise nitrogen fertiliser production, the renewable fertiliser industry is still at an early stage. Given long-term investment, and project planning cycles together with the urgency of the climate crisis, the transformation should not be delayed any longer.

At the moment, carbon pricing does not yet incentivise renewable fertilisers over conventional ones. Despite industry targets for hydrogen there are hardly any policy incentives which support renewable fertilisers. Dedicated policies are needed to secure this new business model and stimulate both 1) ramp up of renewable fertiliser supply and 2) offtake from agricultural producers. The scaling up of renewable fertiliser production and its overall future net greenhouse gas impact will also depend on the deployment of additional renewable energy sources.