Electric heat can slash industry’s fossil fuel use and boost competitiveness

Replacing fossil fuels in industrial processes is increasingly feasible with electricity-based technologies. A study by Agora Industry shows that direct electrification could meet 90 percent of the energy demand not yet electrified by European industry by 2035. Rapid adoption of such technologies would thus make a crucial contribution towards Europe’s climate targets and help ensure the sector’s global competitiveness.

Berlin, 5 June 2024. The generation of process heat required to melt glass, produce food and forge steel is responsible for three quarters of industrial greenhouse gas emissions in the European Union. Switching from mostly fossil fuel-based processes to low-carbon alternatives is therefore critical to reduce the sector’s emissions in line with Europe’s climate targets and ensure its global competitiveness.

A new study commissioned by Agora Industry examines the technical potential of electrification to generate process heat. It concludes that technologies existing today could already provide much of the energy required for process heat. As further technologies reach maturity and are rolled out, this could increase to cover high temperature applications and meet 90 percent of the final energy demand not yet electrified by industry by 2035. Thus, in just over a decade, direct electrification technologies could make much of the fossil fuel currently used for process heat obsolete, the authors find.

“Ensuring Europe’s industrial competitiveness while meeting the bloc’s climate goals has to be a top priority for the next EU policy cycle,” said Frank Peter, director of Agora Industry. “Given the significant potential that direct electrification has when it comes to replacing fossil fuels for process heat, there is a strong case to promote its use and create the right incentives to encourage its adoption.”

Taking electric heat to the next degree

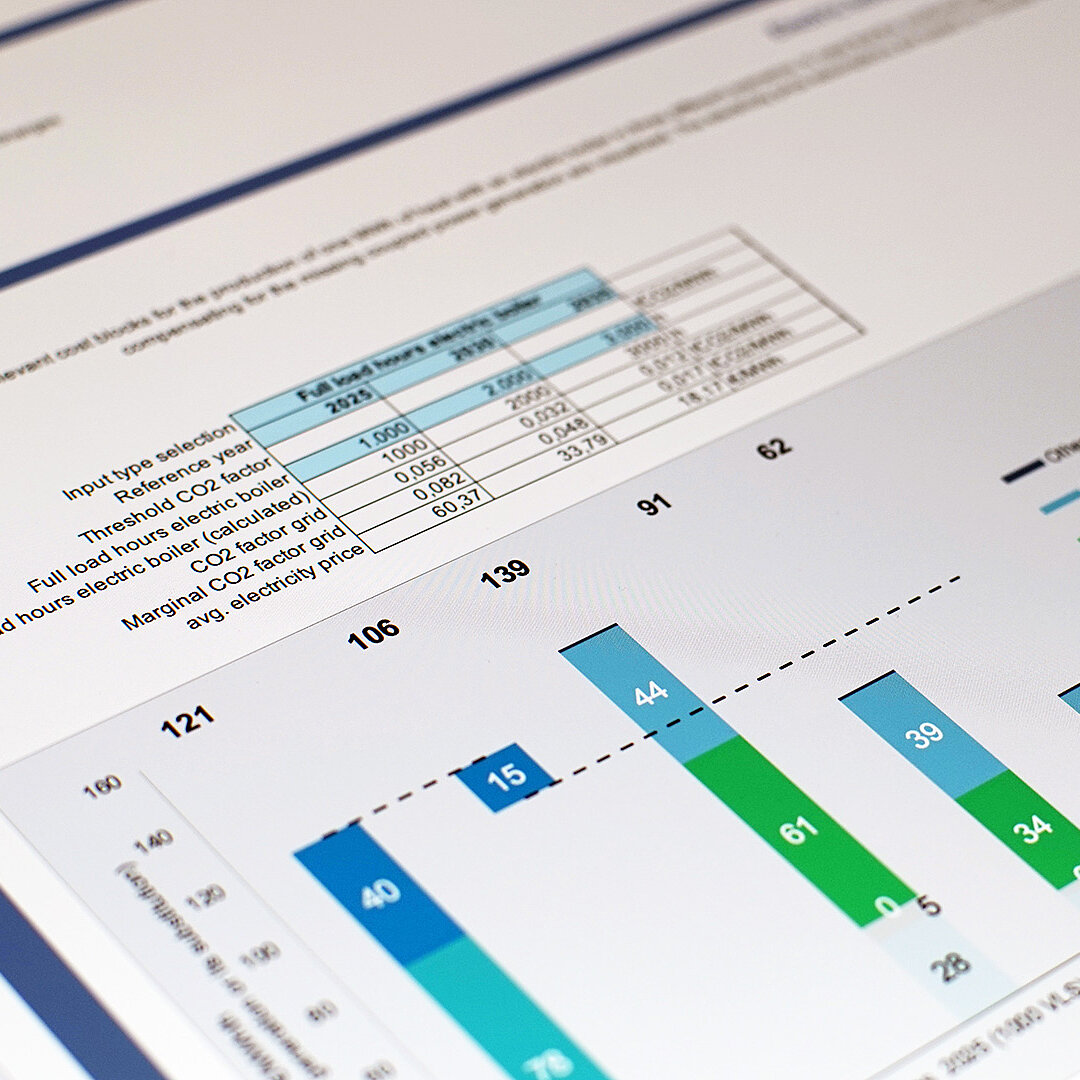

The study finds that large heat pumps and electric boilers can already deliver industrial-scale process heat at temperatures needed for paper production, various chemical processes and the food industry (up to 200 and 500 degrees Celsius, respectively).

Resistance heating and electric arc furnaces can reliably produce temperatures up to the approximately 1 800 degrees Celsius needed to melt metals and plastics, while induction technology can even achieve higher temperatures of up to 3 000 degrees Celsius. The burning of clinker and heating of steel will likely require methods that are still undergoing refinement, such as plasma torches and shock-wave heating. All of these solutions have clear development pathways that make their widespread adoption by 2035 both technologically and economically feasible, given the right framework conditions.

Since industrial processes are often highly site- and product-specific, an individual assessment will be required in each case. There may be situations in which hybrid concepts, such as directly electrified heat and biomass or hydrogen, provide the best solution. However, in the majority of use cases, direct electrification of heat constitutes the most efficient use of renewable energy. The study finds that, of the 2 067 Terawatt hours (TWh) of energy used for process heat across the EU 27 in 2019, all but 208 TWh could be electrified by 2035. For this to occur, a number of barriers need to be removed.

Making full use of electric heat’s potential

Current obstacles to a ramp-up of electrification include the relative cost compared to fossil gas and limits to existing generation and transport capacity for renewable electricity. Industries may also hesitate to make the switch until they see large-scale electrified applications in operation. Uncertainty about future energy infrastructure, or lack thereof, also poses a barrier when it comes to choosing which route to go down. The Agora study identifies possible policy solutions to tackle these barriers.

“The incoming European Commission has the opportunity to send a strong signal on economic and climate ambition by developing an EU industrial electrification action plan,” said Frank Peter. “It should support companies in prioritising electric process heat generation and thus help boost its uptake.”

Such an action plan would include forming an industrial alliance to facilitate market introduction of electrified heat technologies, e.g. by setting deployment targets for heat pumps and e-boilers to enable investments. The action plan should also ensure funding schemes, such as Horizon Europe and the EU ETS Innovation Fund, prioritise direct electrification projects, address accelerated grid access for industry and ensure industrial heat electrification is integrated into grid planning.

The 82-page report ‘Direct electrification of industrial process heat’, commissioned by Agora Industry and produced by Fraunhofer Institute for Systems and Innovation Research, is available for free download down below. The report explores in greater detail the industrial decarbonisation topic discussed in a recent Agora Think Tanks publication ‘EU policies for climate neutrality in the decisive decade’, which outlines 20 priorities for the next EU Commission to advance climate neutrality across the power, industry, agriculture and transport sectors.