This content is also available in: German

Electrification, recycling, and renewable feedstocks – three pillars for a climate-neutral chemical industry

The energy crisis and the more stringent EU carbon market rules require that chemical companies quickly phase out fossil fuels and reduce their emissions. This can be achieved through a combination of better product recycling, a switch to electricity-based process heat and the use of renewable instead of fossil feedstocks.

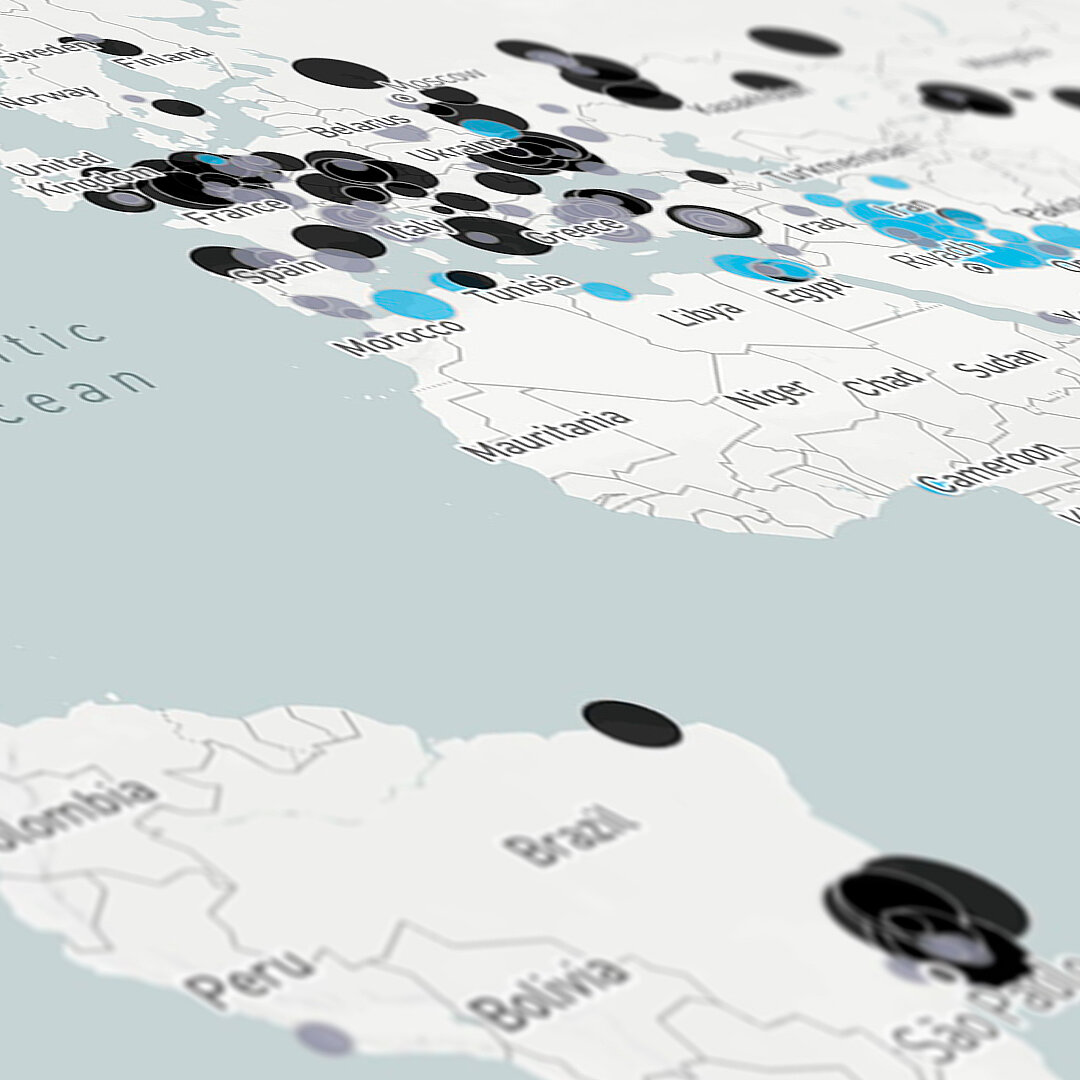

Achieving a climate-neutral chemical industry requires reducing emissions throughout the entire life cycle of chemical products. A new study by the think tank Agora Industry proposes a threefold approach to achieve this. The strategy includes electrification of process heat, better recycling, and reuse of chemical products, and using renewable feedstocks, such as sustainable biomass. This approach would reduce demand for fossil gas and raw materials as well as renewable hydrogen and electricity. By using the carbon contained in biomass, the chemical industry could even bind CO₂ in its products in the long term – if they are recycled repeatedly.

“The chemical industry is facing a paradigm shift, moving away from fossil fuel-based production and quick disposal of products towards renewable feedstocks and a circular economy. This holds enormous potential for emissions reductions as well as new CO₂ storage and sinks,” says Frank Peter, Director of Agora Industry.

According to the Agora Industry study, upstream and downstream greenhouse gas emissions of basic chemicals are even higher than the direct CO₂ emissions from the manufacturing of chemical products. For Germany, the world's largest exporter of chemical products, Agora Industry estimates that emissions from the fossil fuel extraction and the incineration or disposal of the products at the end of life are three times higher than those from the production. More than half of the greenhouse gas emissions related to these basic chemicals occur after their use phase. The extraction of raw materials for basic chemicals also generates emissions as 90 percent of chemical products are based on oil or fossil gas.

High fossil fuel prices and the tightening of the EU Emissions Trading System (EU ETS) rules require a rapid transformation of the chemical industry. The faster declining EU ETS emissions cap means that European industrial companies will have to be climate neutral before 2040. Accompanying policies are needed to achieve this goal. Peter: "A comprehensive policy framework aligned with climate goals is necessary to drive the transition of the chemical sector. Enabling companies to reduce their dependence on fossil fuels will improve their competitiveness and resilience and incentivise the development of new product innovations for an increasing demand of climate-neutral chemicals."

40 percent of the sector’s fossil fuel consumption is used to generate power and heat. In response to the energy crisis, the EU launched the REPowerEU plan which among other things envisages halving of the use of fossil gas in German industry by 2030. Fossil gas in process heat can be replaced by for example heat pumps, electric boilers, or electric steam cracker furnaces. “Against the backdrop of the energy crisis, the future of the chemical industry in Germany and Europe depends more than ever on replacing fossil gas,” says Peter.

According to the Agora study, the electrification of process heat could reduce the total energy demand for heat generation in the German chemical industry by 15 percent compared to today. In contrast, using renewable hydrogen as a fuel substitute would result in an energy demand increase of 31 percent. Renewable hydrogen will, however, be indispensable to produce basic chemicals such as ammonia and methanol, the production of which so far relies on fossil gas-based hydrogen.

Since almost every chemical product contains carbon, improved recycling is another key element of a transformation strategy. “Plastic waste is a completely underestimated resource. Closing carbon cycles rather than burning or disposing products after use reduces both emissions and demand for raw materials,” says Peter. Higher recycling rates and standards are therefore an important part of the transformation.

By introducing recycling-friendly product design and using new chemical recycling processes, recycling rates for plastic waste could be increased from today’s 15 to 75 percent. Plastics recycling will also become more economical with the planned pricing of emissions from waste incineration under the EU ETS.

Better recycling could reduce the demand for raw materials to produce new products by 20 percent compared to today. The remaining demand for climate-neutral chemical products would have to be covered by renewable carbon feedstocks. Renewable options identified in the Agora study include direct air capture of CO2 as well as biomass from waste and residues from the agricultural and wood processing sectors, bio-waste from households and industry, and wood residues that would otherwise be burned, releasing CO2.

"By using biomass as a feedstock, the chemical industry can leverage its potential to store carbon in the long term. The longer the carbon remains bound in products designed for reuse, the better for the climate," says Peter. In Germany today, about a quarter of the biomass produced is burned. Storing the biogenic carbon in materials and products instead would create a temporary CO₂ sink. This means that more CO₂ is bound than released. This climate-positive effect can be maximised in combination with an improved circular economy.

The paper "Chemicals in transition. The three pillars for the transformation of chemical value chains" has been published in cooperation with the data analysis company Carbon Minds and EPSE, a research institute of ETH Zurich on behalf of Agora Industry. The 54-page publication contains an overview of the greenhouse gas emissions of the German chemical industry as well as its energy and raw material consumption and presents a three-pronged approach that reduces emissions throughout the entire life cycle. The publication is available for free download below.

![The global steel industry can achieve net-zero emissions by the early 2040s [Translate to English:]](/fileadmin/_processed_/8/f/csm_15_insights_global_steel_news_73f640a802.jpg)

![Shifting global steel reinvestments from coal to clean [Translate to English:]](/fileadmin/_processed_/9/e/csm_global-steel_project_news_2_283e600f74.jpg)