Forging the future: How to make steel without harming the planet

From buildings to machines, modern economies depend on steel. Once considered a hard-to-abate industry, it is now showing encouraging signs of embracing near-zero CO2 production methods. A new report by Agora Industry examines which of those technologies are best suited to reduce emissions.

11 April 2024. The steel industry is responsible for eight percent of global CO2 emissions each year. With more than seven in ten existing coal-fired blast furnaces due to be refurbished or replaced in the 2020s, there is a key window of opportunity to shift to low-emissions methods of production over the coming years.

The new analysis by Agora Industry, Wuppertal Institute and Lund University assesses eight potential breakthrough technologies for their market readiness, cost and impact on emissions. These methods include deploying hydrogen to produce direct reduced iron, scrap-based electric arc furnaces, iron ore electrolysis and the use of carbon capture in existing coal-based facilities.

The analysis concludes that scrap and hydrogen-based methods of steelmaking hold the biggest promise for those companies aiming to make the switch this decade. By contrast, retrofitting existing coal-based facilities with carbon capture and storage (CCS) methods entails the biggest economic and environmental risk, the authors find.

“We’re seeing the first wave of new low-emissions steelworks taking shape in Europe, China and North America using direct reduced iron technology. This could put the steel sector onto a truly transformational path,” said Frank Peter, director of Agora Industry. “Simply trying to capture CO2 from traditional blast furnaces would mean betting on unproven technology, leaving high upstream emissions and risking considerable stranded assets further down the road.”

Appropriate regulatory frameworks and targeted incentives are necessary to boost demand for low-CO2 steel and encourage its production.

"Governments will choose different ways to support the steel industry, as we have seen with direct financial assistance programmes in Europe and the Inflation Reduction Act in the United States,” said Frank Peter of Agora Industry. “But for production to scale up significantly by 2030 there will also need to be greater international cooperation to create lead markets for low-emissions products, encourage the trade in direct reduced iron and establish clear standards for green steel.”

“Technical solutions to reduce the high CO2 emissions of current steel production to almost zero are within reach,” said Manfred Fischedick, president of Wuppertal Institute. “These solutions must now be quickly implemented and further developed instead of relying on fossil-based technologies that are not compatible with today’s climate protection goals.“

The new analysis, entitled “Low-carbon technologies for the global steel transformation” was prepared jointly with Wuppertal Institute and Lund University. The 76-page publication in English can be downloaded for free below.

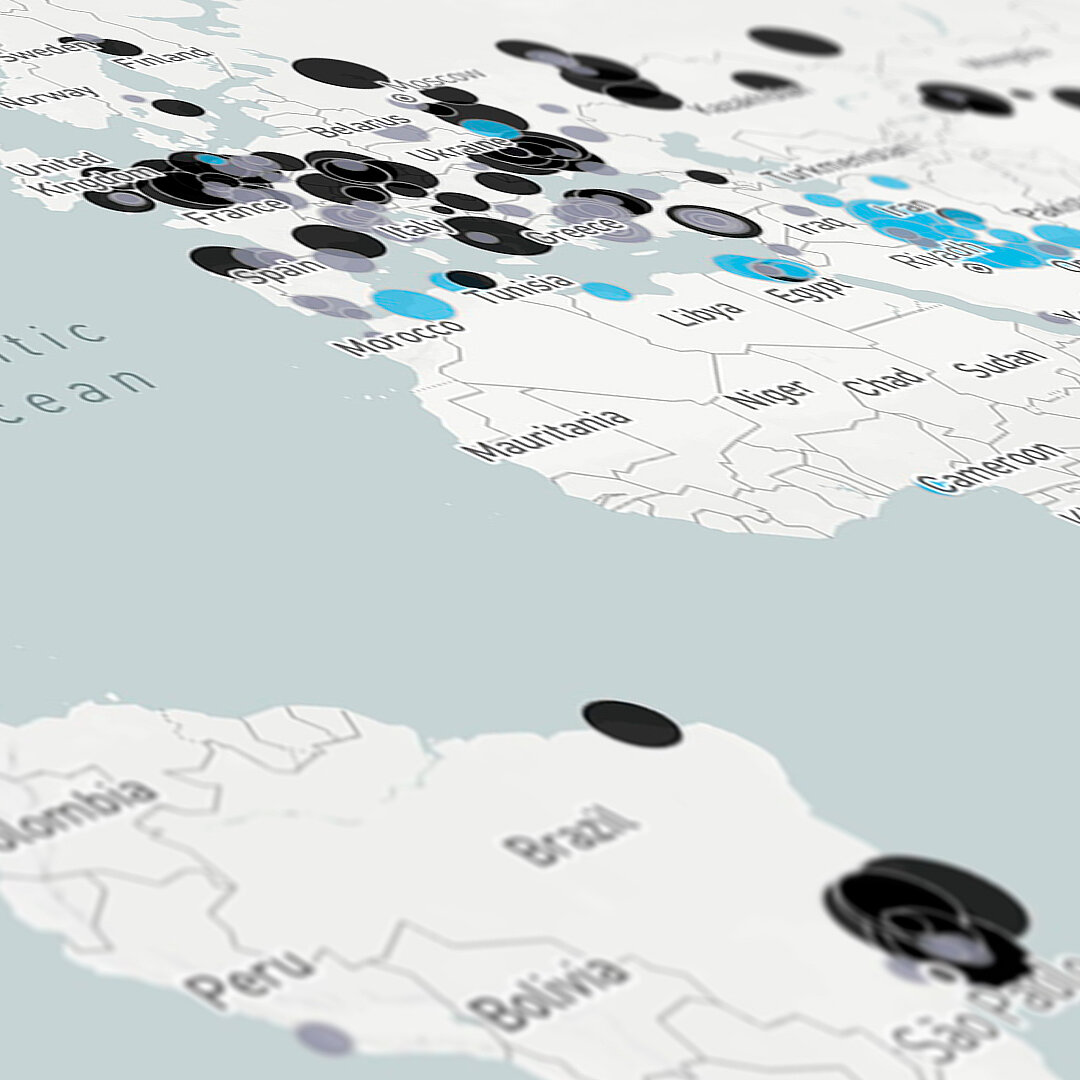

The study is part of a series of Agora Industry publications on the global steel transformation. This includes the Global Steel Transformation Tracker, a digital tool first released in 2021 and updated regularly since. It measures progress in key indicators of the global steel transformation, providing country-specific information on reinvestment and new investment requirements of coal-based steelmaking capacity. It also tracks companies’ announcements on low-carbon steel capacity before 2030. The tracker sheds light on the 2020s transformation gap – that is, whether low-carbon steel announcements in a country are sufficient to substitute coal-based steelmaking capacity that will reach the end of its technical operating life before 2030.

Last year, Agora Industry also published ’15 insights on the global steel transformation,’ which concluded that it is technically feasible for the sector to reach net-zero greenhouse gas emissions by the early 2040s.

![The global steel industry can achieve net-zero emissions by the early 2040s [Translate to English:]](/fileadmin/_processed_/8/f/csm_15_insights_global_steel_news_73f640a802.jpg)

![Shifting global steel reinvestments from coal to clean [Translate to English:]](/fileadmin/_processed_/9/e/csm_global-steel_project_news_2_283e600f74.jpg)