-

The current energy crisis makes it imperative to reduce the EU’s dependency on fossil fuels and imported raw materials.

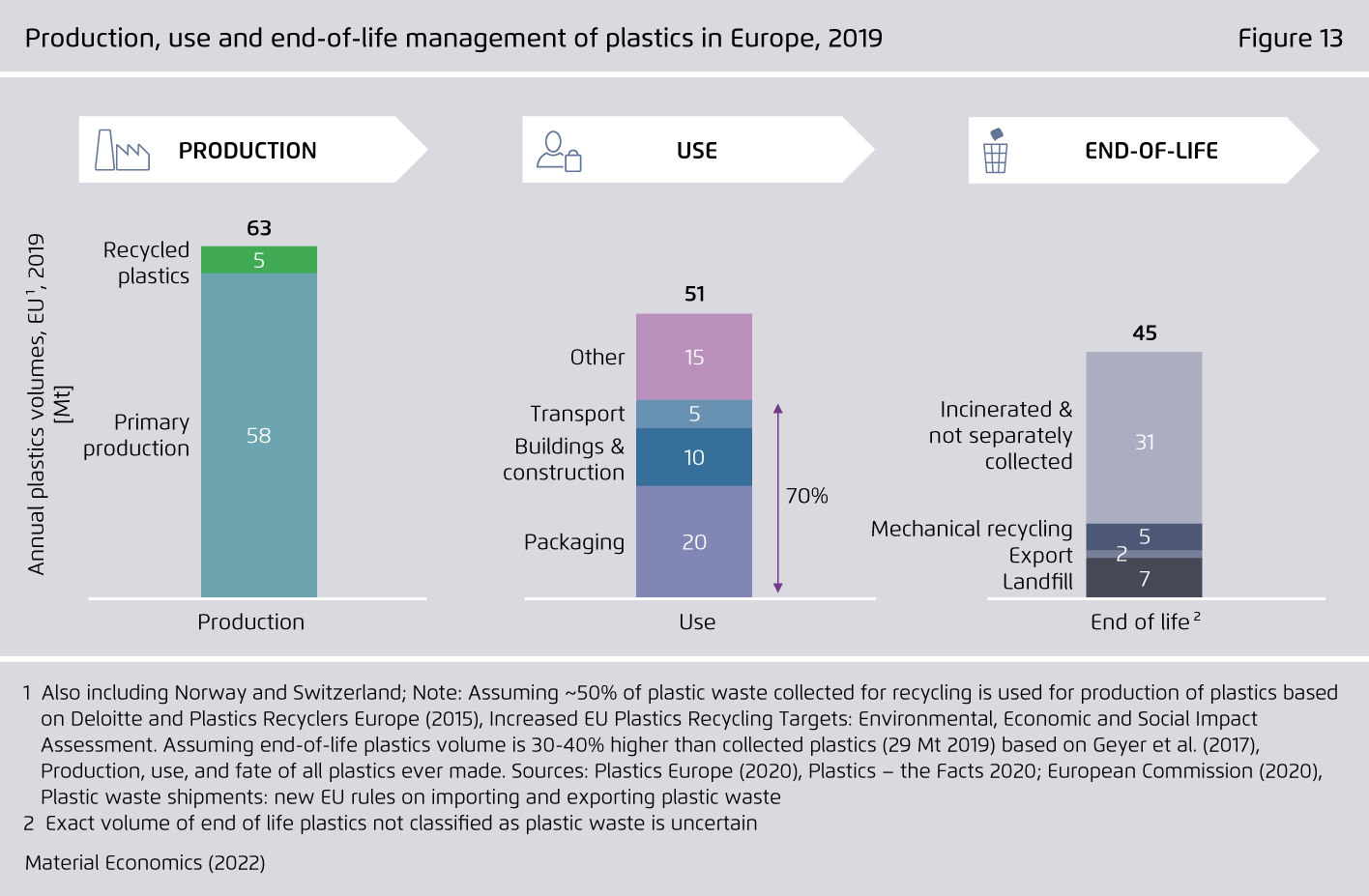

Industrial production of virgin plastics, steel, aluminium and cement alone accounts for 13 percent of yearly energy consumption and 581 Mt of annual emissions. The EU also imports very large amounts of gas, oil and coal to produce plastics and other energy intensive materials.

-

Enhanced recycling and greater material efficiency hold enormous untapped potential for the transition to a fossil free production of energy-intensive materials, in both the short and long run.

With ambitious policies, annual EU industrial emissions could be reduced by up to 10 percent (70 Mt) until 2030 and by 34 percent (239 Mt) until 2050 compared to 2018 levels. Plastics production alone could avoid using fossil fuels equivalent to roughly 2.7 billion cubic metres of gas and 149 million barrels of oil annually by 2030.

-

Realising these abatement and savings potentials must be a priority in the EU’s new Circular Economy legislation. To synchronise energy security and climate neutrality, this legislation must spur demand for high quality recycling while boosting collection and supply of high quality recyclates.

Required policy instruments are expanded quotas for recycled content; investment aid for rapid deployment of innovative recycling technologies; as well as labelling and best practice mandates for collection, sorting, recycling and re-use.

-

EU Member states can now implement key policy measures that effectively reduce greenhouse gas emissions already within the next 1 to 5 years.

Examples are wider bans on single use and non-recyclable plastics, the implementation of deposit-refund schemes for plastic packages, investments into ex-post re-sorting and state of the art recycling practices.

Mobilising the circular economy for energy-intensive materials (study)

How Europe can accelerate its transition to fossil-free, energy-efficient and independent industrial production

Preface

The impacts of Russia’s war on Ukraine have dramatically accelerated the urgency for Europe to phase down its use of fossil fuels, be more energy efficient and reduce the dependence of critical domestic industries. Key will be the transition of European industry to fossil free production basedon domestic resources. 70 percent of EU industrial emissions come from the production of a few key carbon-intensive materials: iron and steel, aluminium, cement and lime, and plastics. These activities also account for a large and growing share of EU energy, and fossil fuel, consumption.

Existing approaches to the industrial transition tend to focus on reducing the carbon intensity of virgin materials production. However, the current European context requires a new approach maximising both industrial energy and resource efficiency with the same level of importance. Increasing and improving closed-loop recycling and developing more materialefficient value chains will be essential. Furthermore, it will play to the EU’s long-term competitive economic strengths, such as digitalisation, logistics and advanced manufacturing technologies.

Material circularity and efficiency would not only reduce the economic costs of the transition but also ensure that the industrial transition is technically and politically feasible within the 2050 timeframe.

Key findings

Bibliographical data

Downloads

-

pdf 6 MB

Mobilising the circular economy for energy-intensive materials (Study)

How Europe can accelerate its transition to fossil-free, energy-efficient and independent industrial production

All figures in this publication

Industry share of total greenhouse gas emissions in the European Union in 2018

Figure 1 from Mobilising the circular economy for energy-intensive materials (study) on page 9

Additional power needs for the direct and indirect electrification of steel, cement and chemicals

Figure 2 from Mobilising the circular economy for energy-intensive materials (study) on page 13

Our experts

-

Wido K. Witecka

Project Manager Industry (until June 2024)